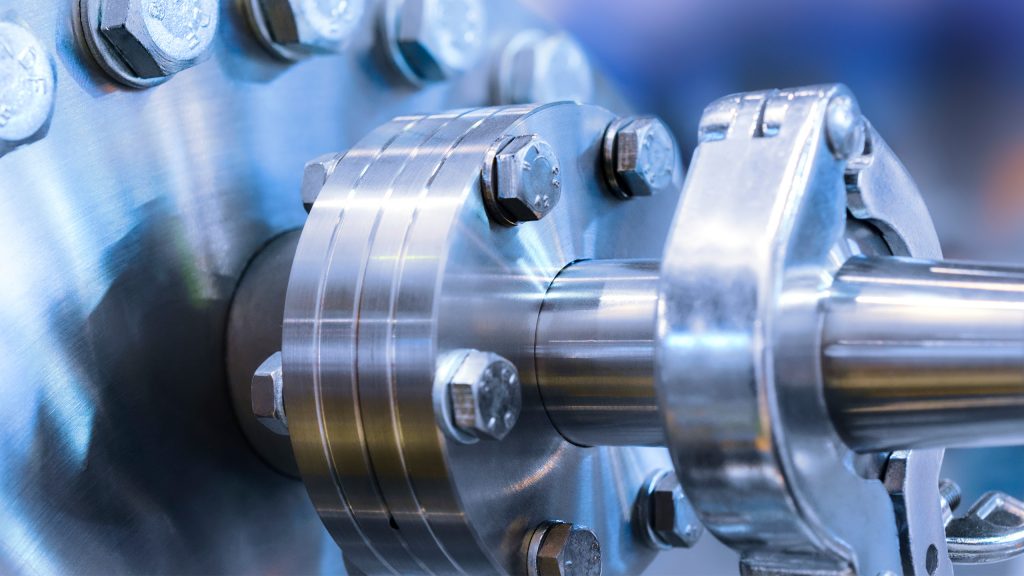

Vacuum Flange

Specification-Vacuum Flanges

| Standards | ANSI/ASME B16.5, B16.48, ANSI Flanges, GOST Flanges, DIN Flanges, EN-1092, B16.47 Series A & B, ASME Flanges, EN Flanges, AWWA Flanges, BS Flanges. |

| JIS Standard | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| DIN FLANGES | DIN 2527, 2627, 2631, 2656, 2576, 2673, 2629, 2628, 2566, 2641, 2637, 2655, 2634, 2636, 2632, 2633, 2638, 2642, 2573, 2635. |

Flanges are Available in Following Materials: | |

| Stainless Steel | SS 201, SS 202, SS 301, SS 304, SS 304L, SS 310, SS 310S, SS 316L, SS 316TI, SS 317, SS 317L, SS 321, SS 347, SS 409, SS 409M, SS 409L, SS 410, SS 410S, SS 420, SS 430, SS 431, SS 441, SS 444, SS 446, SS 17-4PH, SS 904L. |

| Duplex Steel | UNS S32205, UNS S31803 Flange |

| Super Duplex Steel | UNS S32750, UNS S32760 Flanges |

| Carbon Steel | Carbon steel A105 Flanges, A36 Flanges, IS 2062 Flanges, A350 LF2 Flanges, F42 Flanges, F52 Flanges, F56 Flanges, F60 Flanges, F65 Flanges, F70 Flanges, F80 Flanges, IBR flanges, A694 Flanges, SS400, SF440, ST37-2 Flanges, S235JrG2 Flanges, P250GH Flanges, C22.8 Flanges, etc. |

| Alloys Steel | Alloy 20, F1, F5, F9, F11, F22, F91 Flanges |

| Copper Alloys | Cu-Ni 70/30, Cu-Ni 90/10, C 24000, C 75700, C 51100, C 22000, C 27200, C 21000, C 26800, C 52100, C 77000, C 52000, C 11000, C 74500, C 23000, C 28000, C 12200, C 76400, C 51900, C 75400, C 26000, C 51000, C 10200, C 27000 |

| Nickel Alloys | Nickel 200, 201 |

| Inconel | Inconel 600, 601, 625, 718, 800, 825, X-750 |

| Monel | Monel 400, k500 |

| Hastelloy | Hastelloy C-22, C-276, C-4, X |

| Titanium | Grade 1, 4, 5(Ti 6Al-4V), 6(Ti 5Al-2.5Sn), 7, 11, 6Al-2Sn-4Zr-2Mo, Grade 12, 6Al-6V-25n, Grade 23(Ti 6AL-4V ELI), 8Ai-1Mo-1V, Grade 5 ELI, Grade 9(3Al-2.5V), 6Al-7Nb. |

| Aluminium | 6063, 1100, 6082 A96082, 1050, 2017, 2024 A92024, 7050 A97050, 5083 A95083, 2014A A92014, 2011 A92011, 6061 A96061 A86061, 5754, 7085, 2050, 7071 7020, 7178, 5052 A95052, 7150, 7075 A97075 A87075, 7575, 2219, 7175 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Types | Threaded, Plate, Screwed, Forged. |

| Supporting material | Gasket, Ring Joint, Flange Bolts |

| Size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

| Production technique | Forged, machined and Heat treated |

| Custom design | As per your drawing |

| Origin | Indian / USA / Korean / West Europe / Japan |

| Pressure Class | PN 6 TO PN 100 |

| Coating/Surface Treatment: | Zinc Plated, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized. |

| European/African/Russian Standard Flanges | Available |

| Test | Direct-reading Spectrograph, X-ray detector, UItrasonic flaw detector, Magnetic particle detector, Hydrostatic testing machine. |

Marking Standard | Name of Manufacturer |

| Schedule | |

| Type of Flange Facing | |

| Pressure Class | |

| Nominal Pipe Size, etc | |

Test Certificates | EN 10204/3.1B, NACE MR0103, NACE MR0175 |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc | |

VacuumFlanges 150 lb flange Pressure Ratings

| Temperature °F | 150 LBS | 300 LBS | 400 LBS | 600 LBS | 900 LBS | 1500 LBS | 2500 LBS |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

Vacuum Flanges- Dimensions

| Nominal Pipe Size | Outside Diameter of Flange | Thickness of Flange | Diameter of Raised Face | Diameter of Hub at Base | Length Thru Hub | Diameter or Bore | Diameter of Hub at Bevel | Radius of Fillet | Depth of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding Neck | Slip-On Threaded Socket | Lap Joint | Slip-on Socket | Lap Joint | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Vacuum Flanges-Torque Specs

| Size in Inch | Size in MM | Number of Bolt | Bolt Diameter | Thread Type | Bolt Stress lb/in2 | Torque lbf.ft. | Torque Nm |

| 1/2 | 15 | 4 | ½” | UNC | 25,000 | 22 | 30 |

| 3/4 | 20 | 4 | ½” | UNC | 30,000 | 26 | 36 |

| 1 | 35 | 4 | ½” | UNC | 33,000 | 29 | 39 |

| 1 ½ | 40 | 4 | ½” | UNC | 50,000 | 44 | 60 |

| 2 | 50 | 4 | 5/8” | UNC | 50,000 | 86 | 117 |

| 3 | 80 | 4 | 5/8” | UNC | 50,000 | 86 | 117 |

| 4 | 100 | 8 | 5/8” | UNC | 40,000 | 69 | 93 |

| 6 | 150 | 8 | ¾” | UNC | 45,000 | 137 | 185 |

| 8 | 200 | 8 | ¾” | UNC | 45,000 | 137 | 185 |

| 10 | 250 | 12 | 7/8” | UNC | 40,000 | 194 | 263 |

| 12 | 300 | 12 | 7/8” | UNC | 40,000 | 194 | 263 |

| 14 | 350 | 12 | 1” | UN8 | 41,000 | 296 | 401 |

| 16 | 400 | 16 | 1” | UN8 | 40,000 | 289 | 392 |

| 18 | 450 | 16 | 1 1/8” | UN8 | 40,000 | 421 | 571 |

| 20 | 500 | 20 | 1 1/8” | UN8 | 40,000 | 421 | 571 |

| 24 | 600 | 20 | 1 ¼” | UN8 | 40,000 | 588 | 797 |

Vacuum Flanges-Grades Available

| Types | Grade | UNS No | ASTM/ ASME Standards |

|---|---|---|---|

| 304 | TP304 | S30400 | A182 / SA182 |

| 304L | TP304L | S30403 | A182 / SA182 |

| 304H | TP304H | S30409 | A182 / SA182 |

| 316 | TP316 | S31600 | A182 / SA182 |

| 316L | TP316L | S31603 | A182 / SA182 |

| 316H | TP316H | S31609 | A182 / SA182 |

| 321 | T321 | S32100 | A182 / SA182 |

| 321H | TP321H | S32109 | A182 / SA182 |

| 347 | TP347 | S34700 | A182 / SA182 |

| 347H | TP347H | S34709 | A182 / SA182 |

| 317L | TP317L | S31703 | A182 / SA182 |

Application

- Food & Beverage

- Paper Industry

- Pharmaceutical

- Hospital Equipment

- Textiles

- Dairy

- Aircraft

- Chemicals

- Others Parts in Machinery

Testing

- Hydrostatic Test

- Macro Test

- Ultra Sonic Test (UT)

- Micro Test

- Hardness Test

- Radiography Test

- Pitting Resistance Test

- PMI Testing

- Mechanical Testing

- X-ray detector

Packing

- Wooden Boxes

- Shrink-Wrapped

- Carton Boxes

- Wooden Crates

- Wooden Pallets